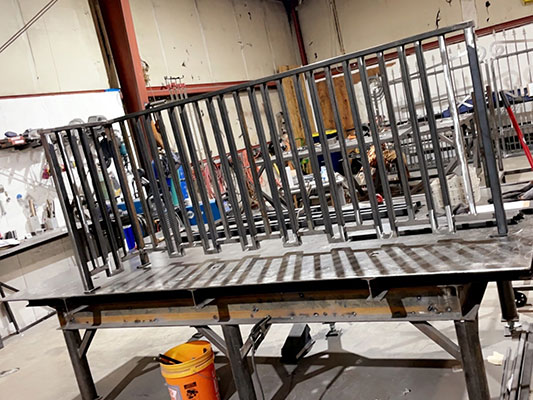

Custom Fabrication

Built and Customized for Each Project

Custom metal fabrication can be used to create a wide range of products, including industrial machinery, architectural metalwork, aerospace components, medical equipment, automotive parts, and more. Some of the most commonly used metals in metal fabrication include steel, aluminum, brass, copper, and titanium.

Custom fabrication involves designing, creating, and manufacturing metal components or structures according to specific requirements and specifications provided by the client. It involves various processes such as cutting, bending, welding, machining, and assembling metal parts to create a finished product.

Custom fabrication requires specialized knowledge and expertise, as well as access to advanced equipment and tools. This is why many businesses and individuals turn to professional metal fabricators who have the necessary skills and resources to produce high-quality metal products that meet their specific needs.

Benefits of Custom Metal Fabrications

It is a process that involves designing, creating, and manufacturing metal components or structures based on specific requirements and specifications provided by clients. This service provides numerous benefits, including:

Tailored Solutions

Allows clients to receive products that are tailored to their specific needs, rather than settling for off-the-shelf solutions that may not fit their requirements.

High Quality Products

Improved Efficiency

Helps improve efficiency by creating products that are specifically designed for optimal performance and functionality.Metal handrails provide a sturdy and secure support system, helping to prevent accidents and injuries.

FAQs for Metal Fabrications

Custom metal fabrication can be used to create a wide range of products, including industrial machinery, architectural metalwork, aerospace components, medical equipment, automotive parts, and more.

Metal fabrication handrails can be made from a variety of materials, including stainless steel, aluminum, and wrought iron.

The cost varies depending on the complexity of the product, the type of metal used, and other factors. However, in many cases, the cost of custom metal fabrication is competitive with off-the-shelf solutions.

The timeline depends on the complexity of the product, the type of metal used, and other factors. However, professional metal fabricators work efficiently to complete projects within reasonable timelines.